Description

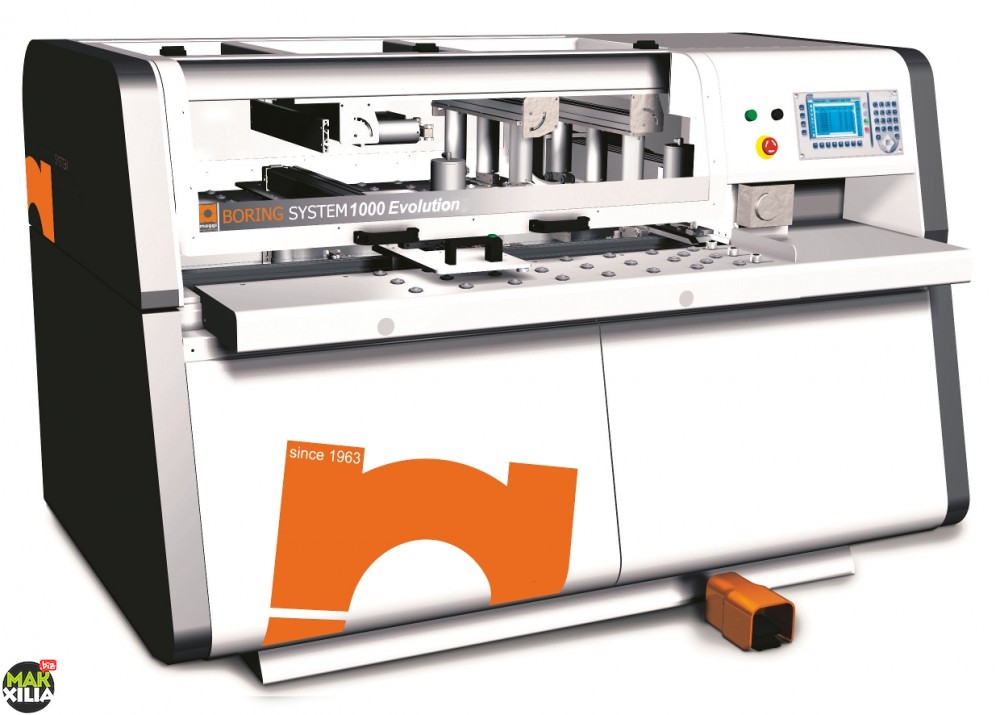

THROUGHFEED PANEL N.C. AUTOMATIC BORING MACHINE

mod. BORING SYSTEM EVOLUTION 1000 – As per E.C. rules –

BORING FROM DOWN AND/OR

AUTOMATIC RETURN TO THE OPERATOR

Thanks to its extreme use versatility and production speed,

the AUTOMATIC BORING MACHINE – BORING SYSTEM EVOLUTION 1000,

represents the ideal solution for people who must o change the type of panel.

STANDARD EQUIPMENT

Automatic Boring Machine – Boring System Evolution 1000:

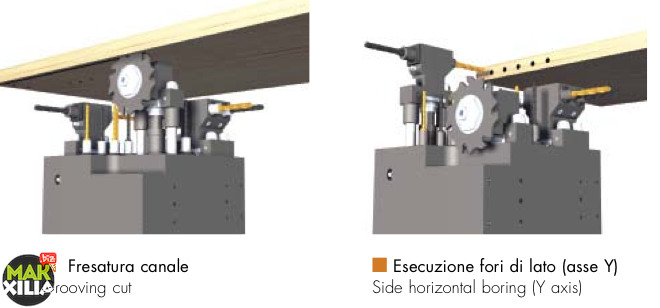

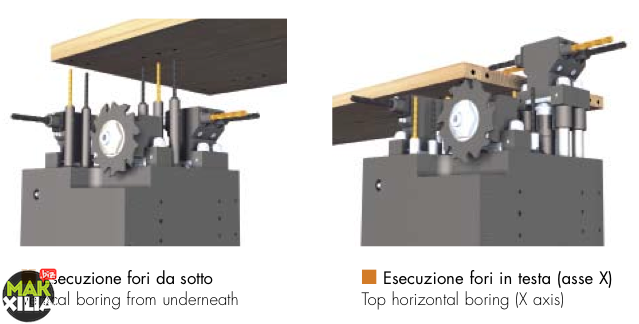

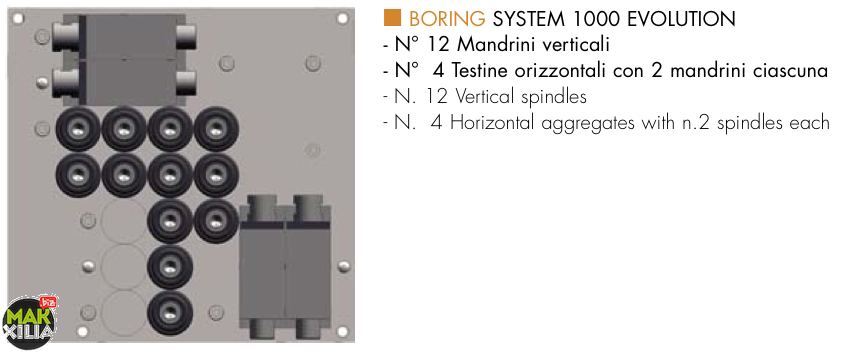

MULTIPLE HEAD composed by:

– Nr. 9 Vertical chucks / Working field Y=1000 mm

– Nr. 4 Horizontal chucks / Working field Y=1000 mm

BUILT-IN CONTROL IN THE MACHINE:

– Operator’s interface mod. ICE 101 Windows CE, maker CNI

– Touch-screen 7″ colour screen

– USB door

SUPPORT TABLES:

– Front and rear mm. 800×300

MULTI-CHUCK HEAD

It allows to work panels on 5 sides. Workings are made from down for greater precision, cleaning and care of panels.

Blade group for realization of slots on panels, available on the mod. Boring System 800 S-Evolution.

CONTROL CONSOLE

Control console integrated in the frontal part of the machine, equipped with “touch screen” colour display, software for boring programming and Windows as per E.C. rules

Boring programmes, tool tables and work bills are memorized and managed through simple menu of easy navigation. the program management, can be directly made in the machine and/or from the office.

X – Y ZERO SETTING SYSTEM

X-axis zero setting happens automatically thanks to 2 pneumatic datum stops that activated when panels are loaded.

If required, the position of datum stops can be also adjusted by hand, f.e. when half-worked panels with horizontal pins inserted are used.

Y-axis zero setting is made by hand thanks to the system with pneumatic clamping of counter-pliers group.

The position is adjusted according to panel width.

DOUBLE CLAMPING PLIERS

The automatic translation system of panels is extremely steady thanks to the double pneumatic clamping pliers.

It’s possible to position and drill either shaped or round panels.

It’s given as standard on the mod. Boring System 1000-Evolution.

ASPIRATION

The boring machine mod. Boring System Evolution has a double suction system that is directly connected to the boring unit and a centralized chips collecting system.

HOLDING STRUCTURE

The welded and machined steel structure ensures the maximum stiffness and working precision.

The movement system is based on guides and ball blow-by slides with lateral seals and dust-scrapers.

The movement of the boring unit and of clamping pliers happens through ball blow-by screws driven by “brushless” electric motors.

Centralized lubrication system.

SUPPORT ROLL-WAY (ACCESSORY).

Useful for working very large panels. Extractable up to 350 mm. and equipped with anti-scratch sliding balls. Appliable on both sides of the machine.

SUPPORT TABLES

Double support table – front and back – (300×800 mm), with anti-scratch sliding balls, useful to facilitate panel loading and unloading.

Panel loading and unloading can be continuous cycle or fore, only, towards the operator.

Unlimited panel length.

As standard equipment on the mod. Boring System 1000 Evolution.

TECHNICAL DATA

AUTOMATIC BORING MACHINE – BORING SYSTEM EVOLUTION 1000

– Number of chucks: 12 vertical + 4 horizontal

– Distance between chucks mm. 32

– Number of controlled axis: 3 (X Y Z)

– Min. width of panels mm. 80

– Max. width of panels mm. 1200

– Min. thickness of panels mm. 10

– Max. thickness of panels mm. 60

– Max. boring depth mm. 63

– Max. boring diam. mm. 35

– Max. working dimension of the Y axis mm. 1000

– Max. working dimension of the X axis = unlimited

– Max. speed of the X axis 42 mt/min

– Max. speed of the Y axis 25 mt/min with panel

– Max. speed of the Y axis 42 mt/min without panel

– Max. speed of the Z axis 15 mt/min

– Speed of panel movement 30 Mt/min.

– Chuck rotation speed 3200 r.p.m.

– Motor power kW 3,0

– Suction hose diam. mm. 100

– Pneumatic working pressure 6 Bar

– Overall dimensions mm. 2200x1500x1500

– Height of the worktable from the ground mm. 900

– Net weight Kg. 1200