Description

AUTOMATIC EDGE BANDING MACHINE

mod. KC-50 – “PHOTO FOAM version”

WITH GLUE POT AND CHAIN FEEDING – As per E.C. rules

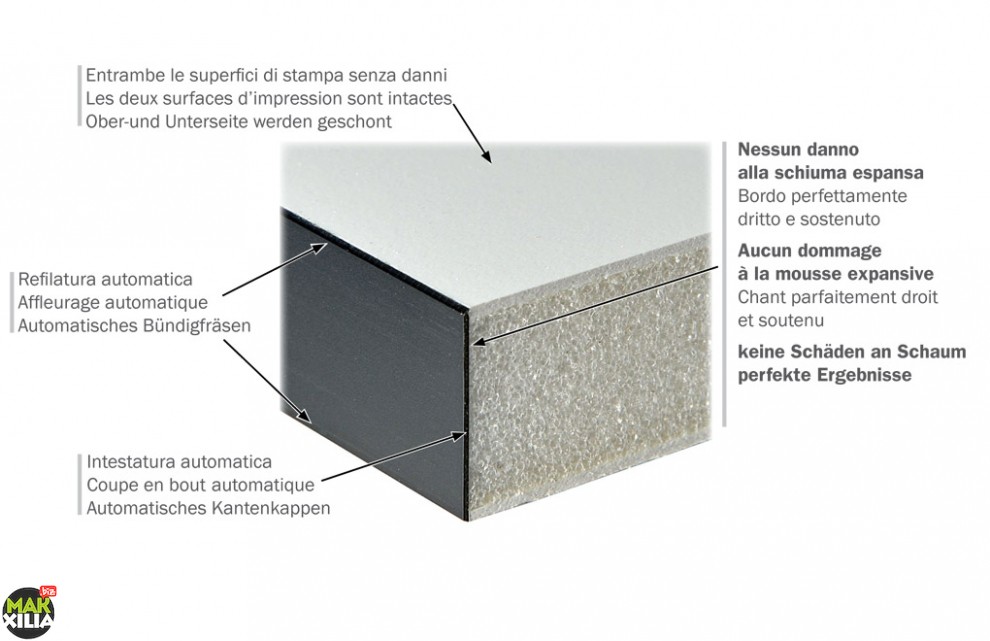

For pre-glued edges on light straight panels SUITABLE FOR, AND USED IN THE ADVERTISING FIELD and PHOTOGRAPHY.

AUTOMATIC EDGE BANDING MACHINE mod. KC-50 – PHOTO FOAM

TECHNICAL FEATURES

– Logic working controlled by PLC with thermoregulator – automatic stand-by

– it can apply edges up to mm. 0,8 thick

– chain panel feeding with rubber-coated slides

– height-adjustable upper bar with double row of rubber-coated wheels for panels min. 8 mm – max 45mm, with numerical indicator

– automatic roll-edge feeding through motorized rubber-coated roll

– pneumatic shears to cut bobbins

– Teflon-coated glue pot, 7 electric resistences – capacity about 2 kg.

– 3 pressure rolls with numerical position indicator – 1st floating aluminium roll – the 2nd and 3rd aluminium ones

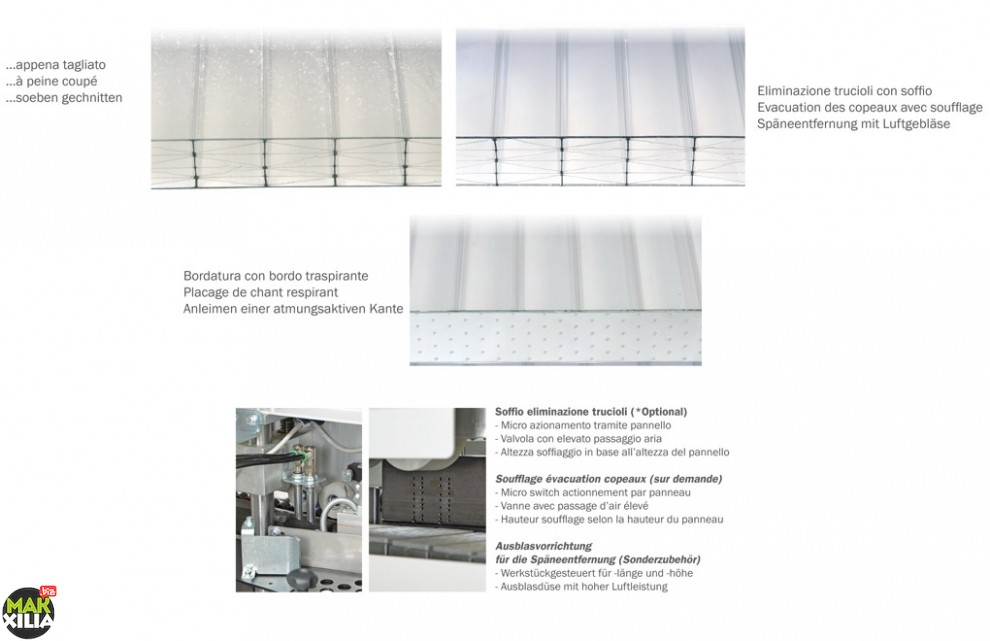

– front/back automatic/pneumatic hooking/run butting device (shears)

– 0-25-degree tilting trimming devices combined milling cutters with 4 teeth/30-degree bevel

– trimming unit motors kW 0,22 – 200 Hz – 12.000 r.p.m.

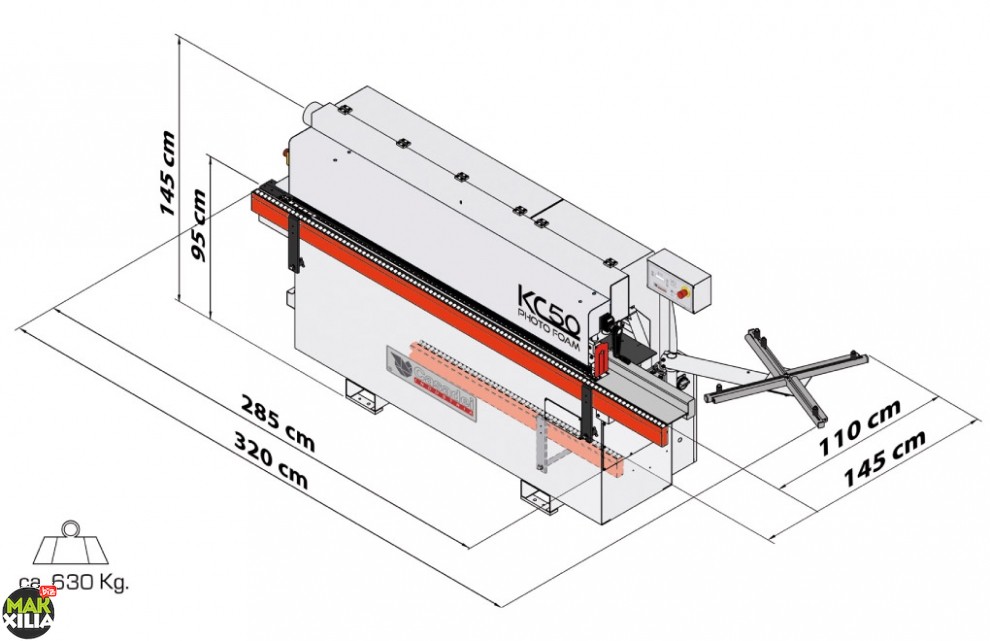

– extendable frontal support for large panels

– bobbin roll support diam. mm. 800

– openable back locking with suction hose D. 120 mm – E.C. marking

– weight kg. 720

– standard voltage Volt 400 / 3-phase / 50 Hz

– on request: Volt. 220/ 3-phase / 50 Hz

TECHNICAL DATA

– min./max. panel thickness mm. 10-45

– max. edge thickness mm. 0,4/2

– resistence power (nr. 5) about 1150 W- trimming unit motor 0,22 kW

– Widia combined milling cutters ray/bevel 10000 r.p.m. – diam. mm. 75 Z4 – ray mm. 2/bevel 30°

– total installed power about 2 kW

Price free factory – wooden feet and thermoretractable cover